Log Washers

Detailed Product Description

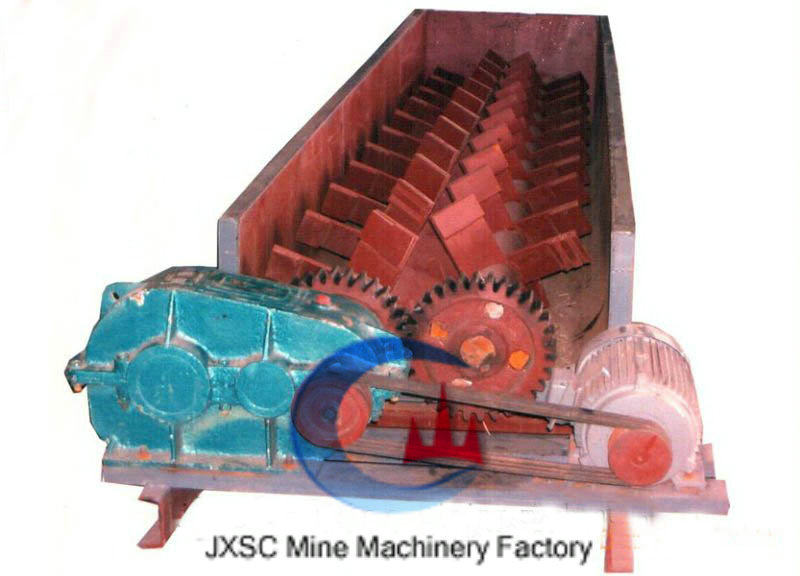

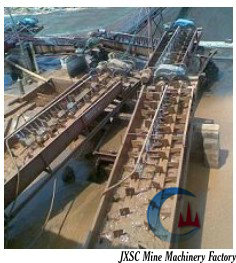

Log Washers are ideal for scrubbing difficult material, Tough insoluble clays, conglomerates and soft stone, and aggregates

Features

- Log Washers ideal for scrubbing difficult materials such as tough insoluble clays, conglomerates, soft stone and cemented aggregate

- High capacity

- Heavy duty conveying paddles

- Fabricated with heavy duty tubs

- Oversize bearings and gears

- Thick-walled shafts

- Lower end bolted to fully machined stub shaft. Upper end mounted through flexible coupling to output shaft of gearbox

- The compound drive divides the operating load over an optimal combination of oversized helical and spur gears

- Continuous grinding and abrading log washer paddles

- Adjustable water discharge gates on both sides of lower end of the tub

Descriptions

Our Log Washers are ideal for scrubbing difficult material. Tough insoluble clays, conglomerates and soft stone, and certain cemented aggregates are too difficult to clean properly in normal screw machines. The log washer thoroughly scouring, breaks down, and cleans the toughest materials. These high quality, highly durable machines perform well under the toughest clay conditions with minimum power, water and downtime.

Feed material is normally delivered between two to four feet from the feed end of the box and is subjected to an aggressive washing action resulting from the intermeshing paddle design. The paddles perform two functions: they help convey material and are the catalyst to material on material scrubbing. The clean material works uphill, between the shafts, and is discharged out the bottom of the box. Deleterious materials are absorbed into water and carried over a weir on either side of the box. The length of the washer box is dependent upon the percentage and tenacity of clay or the waste to removed.

Technical Specifications

| Model |

Spiral Dia.

(mm) |

Rotating Speed

(r/min) |

Feeding size

(mm)

|

Tank slope

(o) |

Output

(t/h)

|

Power

(kw)

|

Weight

(t)

|

| 2RXL320 |

¦µ320¡Á3200 |

28 |

¡Ü30 |

¡Ü12 |

10 |

4 |

0.9 |

| 2RXL400 |

¦µ400¡Á4600 |

23 |

¡Ü30 |

¡Ü12 |

20 |

5.5 |

1.9 |

| 2RXL540 |

¦µ540¡Á4600 |

23 |

¡Ü30 |

¡Ü12 |

25 |

7.5 |

3.9 |

| 2RXL750 |

¦µ750¡Á7600 |

22.7 |

¡Ü70 |

¡Ü12 |

50 |

40 |

17.2 |

| 2RXL800 |

¦µ800¡Á7600 |

22 |

¡Ü70 |

¡Ü12 |

70 |

45 |

18.9 |

| 2RXL914 |

¦µ914¡Á7600 |

21 |

¡Ü70 |

¡Ü12 |

100 |

55 |

23 |

|