Shaking table

concentrator table is applicable for separations of fine-grained and micro-grained rare metal, ferrous and non-ferrous metal, precious metal , coal and other minerals. It can carry out ore concentration operation independently and also can operate in conjunction with jig, screw separator, centrifugal separator and other equipment. The product is made by the only manufacturer designated by the former Ministry of Geology and Mineral Resources, in compliance with the Industrial standards.

LS Shaking Table (shaker table for gold) is to make separations based on the difference of specific gravity of feed materials, reciprocating asymmetrical movement and the stratification performance of the inclined table surface in the lateral water flow with obvious zone of the minerals with different specific gravities on the table, high quality of concentrates produced, convenient operation and adjustment and other features.

spiral concentrator surface is constructed of ore sand or slime and is made up of glass fibre reinforced plastic or aluminum alloy.

LS glass steel shaking tables are effective gravity separation equipment which can be used for different operation such as rough selection, elaborate selection and scavenging for large, medium and small-sized factories and applies to the sorting of nonferrous metal, ferrous metal, rare and precious metal, gold and nonmetallic ores of fine grains. Such shaking tables are divided into ore sand tables and ore slime tables. Ore sand tables apply to the sorting of coarse ores and ore slime tables apply to the sorting of fine ores.

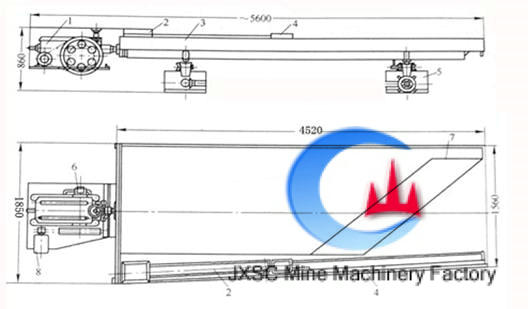

2.Main technical parameters

|

Name |

Unit |

Course ore Deck |

Fine sand

Deck |

Slime Deck |

|

Deck Size |

Length |

mm |

4450 |

4450 |

4450 |

|

transmission end width |

mm |

1855 |

1855 |

1855 |

|

Concentrate end width |

mm |

1546 |

1546 |

1546 |

|

Maximum Feeding Size |

mm |

2 |

0£®5 |

0£®15 |

|

Feeding Amount |

t/d |

30-60 |

10-20 |

15-25 |

|

Feeding Density |

% |

25-30 |

20-25 |

15-25 |

|

Stroke |

mm |

16-22 |

11-16 |

8-16 |

|

Frequency |

f |

45-48 |

18-53 |

50-57 |

|

Water added |

t/d |

80-150 |

30-60 |

10-17 |

|

Transverse slope of Deck |

¡ã |

2¡ã30-4¡ã30 |

1¡ã30-3¡ã30 |

1¡ã-2¡ã |

|

Longitudinal slope of Deck |

¡ã |

1.4 |

0.92 |

------ |

|

Beneficiation Area |

m2 |

7.6 |

7.6 |

7.6 |

|

Cross-section Shape of Deck |

|

rectangular |

saw tooth |

triangle |

|

Motor Power |

KW |

1.1 |

1.1 |

1.1 |

|

Transmission Mechanism |

|

Eccentric linkage |

6-S Shaking Table ( Ordinary Type )

Shaking Table ( Double-Decked Big Channel Steel Support)

6-S Shaking Table ( Small Groove Steel Bracket )

6-S Shaking Table ( Big Channel Steel Support )

II. Structure and Working Principle

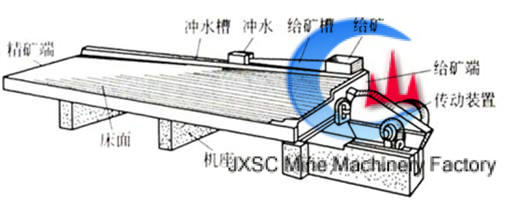

The working principle of this machine is to use the combined action of the specific gravity difference of sorted minerals, alternating movement of bed surface, and transverse oblique water flow and riffle (or notch groove), to allow loose layering of ores on the bed surface and fan-shaped zoning. Then different products can be produced.

This machine is composed of three parts, i.e. head of shaking table, surface of shaking table, as well as bearing and adjusting gradient.

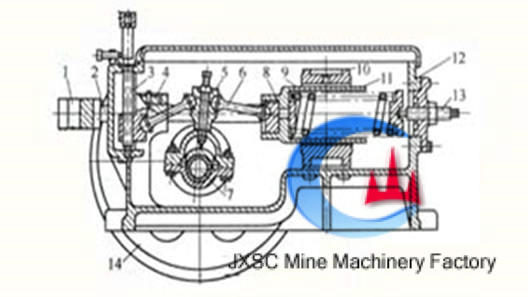

1. Head of shaking table: This is eccentric connecting-rod type mechanism. The motor drives the eccentric shafts to rotate and the connecting rod to move up and down. When the connecting rod pushes down the toggle plate compression spring, the pull rod drives the table surface to move in the direction of table head. When the connecting rod pushes it upward, it, through the spring tension, drives the table surface to move in the opposite direction. When they are linked, the rotating motion of eccentric shaft is changed into horizontal alternating differential motion of table surface.

2. shaker table for gold Table surface: It is mainly composed of vibrating roof, steel skeleton, glass fiber reinforced plastics and wear-proof surface, feed water tank, feed chute, and draw bar. The table surface adopts steel skeleton FRP composite structure. That is, glass fiber reinforced plastics are pasted on steel skeleton to form a solid glassfiber reinforced plastic surface. Its above uses abrasion-proof materials to make surface and riffle (notch groove).

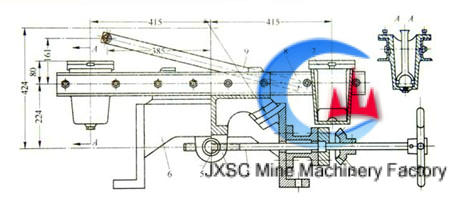

3. Bearing and Adjusting Gradient Mechanism shaker table for gold The bearing and adjusting gradient mechanism is mainly composed of shaking support plate, adjusting seat board, saddle seat, and adjusting screw rod. The shaking support plate enables the table surface to make arc forward and backward alternating movement on vertical plane. The shaking support plate and shaking box are fixed on the adjusting seat board with gripping channel steel. When hand wheel regulating screw rod is used to get the adjusting seat board to rotate on the saddle seat, the Transverse gradient of table surface can be adjusted. |